Job Galvanizing Business

In our job galvanizing business, we have contributed to establishing stable social systems and building infrastructures by extending lifetime of steel structures through their anticorrosive surface treatment of galvanizing.

Also we have tried to realize a vision that makes Hanamaki City in the Tohoku region “a mecca of hot dip galvanizing and zinc-aluminum alloy plating” where our Tohoku Galva Center is located having automated facilities that are mindful of the surrounding natural environment, and having one of the largest zinc kettles in eastern Japan. For its realization, we have been seeking further academic studies in collaboration with other business divisions, too.

Services

Hot Dip Galvanizing

Hot dip galvanized coatings have excellent corrosion resistance and adhesion, and enable surface treatment in every nook and cranny uniformly. They are supposed to be the most economical and effective method for preventing iron rust due to the advantage of maintenance-free after processing. (Service life quoted from JIS H8641 2007: 62 years in urban industrial areas, 113 years in rural areas, and 25 years in coastal areas)

canopy frame

multi-storey car park

Products to be galvanized: various construction structures, port facilities (e.g. breakwater and wave-dissipating fence), facilities relevant to roads and railroads (e.g. bridge, column for sign, signal pole, lighting pole, guardrail, grating, snow shelter, rockfall prevention fence, soundproof wall, etc.), facilities relevant to electric power and telecommunication industries (e.g. steel tower, steel structure, trestle, line hardware, etc.) and so on

Appurtenant tasks: white rust prevention treatment, friction surface treatment (phosphating), masked galvanizing, tagging, assortment work, painting after galvanizing, long-term storage, delivery, etc. Steel frame processing is also available if including galvanizing services.

Dull Finishing (Phosphating)

Dull finishing is a post-galvanizing surface treatment that reduces metallic luster of galvanized surfaces. This treatment is suitable for harmonizing with natural environment and/or requiring quiet atmospheres, and can be used as a surface preparation before painting for galvanized products. There are two types of tints in this treatment; bright-finish N7.0 and dark- finish N4.5.

louver

canopy frame

Galvanizing Kettles Size

Tohoku Galva Center (located in Hanamaki, Iwate Pref.), Capacity: 2500 tons per month. JIS certificated factory

Galvanizing kettle size: L14.0, W2.1, D3.3 (m)

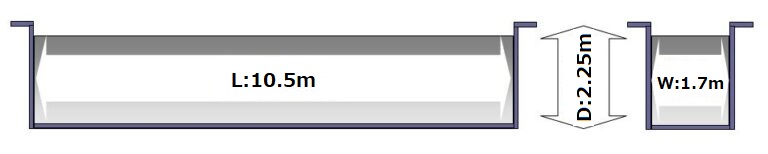

Tohoku Factory (located in Soma, Fukushima Pref.), Capacity: 2000 tons per month. JIS certificated factory

Galvanizing kettle size: L10.5, W1.7, D2.25 (m)

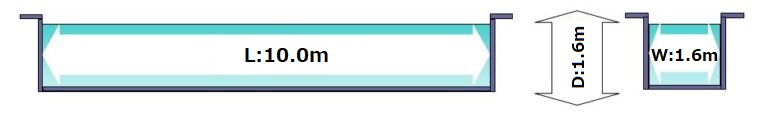

Dull finishing kettle size: L10.0, W1.6, D1.6 (m)